Product Description

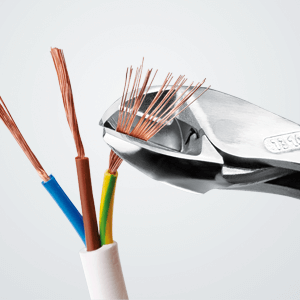

cuts finest strands as well as multi-core cables and piano wires. Powerful, light and universal. High cutting performance with minimum effort due to optimum coordination of the cutting edge angle and transmission ratio. Box-joint design: highest stability with low weight. Doubly supported joint axis for heavy duty. Large opening width for thicker cables. Cuts precisely, even through fine copper wires. Compact, low-weight construction. Universally usable, in the assembly, maintenance and production. 40% less force required compared with standard diagonal cutters of the same length.

Technical attributes

| Length | : | 165 mm | |

| Width | : | 60 mm | |

| Height | : | 28 mm | |

| Weight | : | 175 g |

Video

Detailed description

| Compact tool for big tasks Accurate cuts on thin wire, thick cable and spring steel Thanks to the geometry of the cutting edges and the high-quality chrome vanadium tool steel, accurate cuts of fine copper wire as well as thick, multicore cable with a diameter of up to 12 mm are possible using the Knipex 73 05 160 X-Cut. The cutting edges of the X-Cut bite their way unperturbed through nails and all kinds of wire through to spring steel wire (piano wire). Big energy savings due to high transmission ratio of manual force The small tool that is big on energy saving. The extremely high transmission of manual force leads to around 40 % less effort required compared to conventional diagonal cutters of the same length. Weight only 175 g, length only 160 mm and a large opening width: the ideal statistics for this compact tool. |

Tough and strong: box joint design, double guide and double mounted joint axle

The design of these compact diagonal cutters with box joint design offers the greatest possible stability because the handles of the pliers stabilise each other in the joint: the joint axle of the Knipex 73 05 160 X- Cut is mounted on two sides; the edges of the inner pliers handle are guided on either side. The quality chrome plating permits simple cleaning and is also an advantage if the tool is, for example, kept permanently in a service vehicle where condensation may arise due to changing temperatures. The chrome plating provides effective corrosion resistance. This is, of course, of particular relevance if work is frequently conducted in damp environments.

| Knipex quality – Made in Germany Professional users expect a tool quality that permits simple and safe work and which will also last for several years of hard use. We therefore forge our tools from quality materials, machine them with great precision on up-to-date machinery, and harden them carefully using repeated heat treatment. More than 130 years of specialist pliers expertise is in every pair of Knipex pliers |

Short overview

- High transmission compact diagonal cutters

- Accurate cuts on soft Cu wire and other soft types of wire up to Ø 4.8 mm

- Also suitable for piano wire (spring steel wire)

- Box joint for guide on both sides and less load on the rivet

- Compact format: only 160 mm long

- Low weight (175 g)

- Production according to higher standards for optimal work results and a long service life

- Sit firmly in the hand thanks to multi-component grips

- Forged from high performance chrome vanadium steel, oil hardened in multiple stages, chrome-plated

The X-Cut cuts cable with a diameter of up to 4.8 mm.

Fine wire is cut cleanly thanks to the accurate cutting edges over the entire length of the cutters.

Piano wire, one of the hardest classes of wire, can be cut up to a diameter of 2.2 mm.

The box joint design ensures greater stability with low weight.

Additional products