Product Description

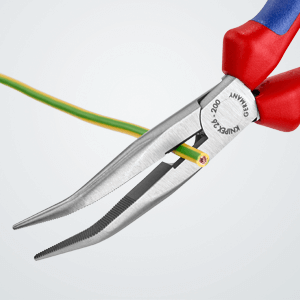

Elastic tips: dimensionally stable even when twisted. Distortion-tolerant, elastic precision tips. Half-round, long, tapered jaws. With cutting edges for soft, medium-hard and hard wire. Cutting edges additionally induction-hardened, cutting edge hardness approx. 61 HRC. 40° angled jaws.

Technical attributes

| Length | : | 205 mm |

| Width | : | 53 mm |

| Height | : | 19 mm |

| Weight | : | 197 g |

| Handles | : | With multi component grips |

| Head | : | Polished |

| Beve | : | Cutting edges with bevel |

Detailed description

| Ideal for use in the electrical, motor and plumbing professions Pliers for gripping and holding – and for powerful cutting The forged and oil-hardened snipe nose side cutting pliers from Knipex are primarily used for instalation and assembly work and for the alignment of components. In addition to the typical tasks for needle nose pliers, they can also be used for powerful cutting. Their cutting edges are shaped to produce a bite type cut – and they have been induction hardened, so that the Knipex 26 22 200 can even be used to cut hard wire. Strong when cutting – inherently stable also when twisted The precision tips at a 40° angle made of vanadium electric steel are elastic and stable when twisted. This allows the manual force deployed to be well measured – forcefully where necessary. The position of the cutting edges near the joint is advantageous for the transmission of force. Cutting capacities of up to Ø 3.2 mm for medium-hard wire and up to Ø 2.2 mm (hard wire) are achieved. Poorly accessible areas can be reached easily with these pliers The round nose pliers from Knipex have very long tips that are also angled at the front. This enables the user to grip low-lying, difficult to reach components accurately and powerfully using these pliers. The benefits of these snipe nose side cutting pliers will be appreciated as soon as you have mastered your first challenge with these pliers from Knipex – such as attaching a hose onto a difficult to reach nozzle. |

| Knipex quality – the snipe nose side cutting pliers The snipe nose side cutting pliers from Knipex are a tool predominantly for assembly work in poorly accessible areas. Those who use tools professionally every day expect a quality that permits simple and safe work and which lasts for many years of hard use. We manufacture our tools from quality materials, machine them with high precision on modern machinery and harden them carefully with multiple stage heat treatment. Every pair of Knipex pliers represents more than 130 years of specialist know-how. |

Short overview

- Needle nose pliers (snipe nose side cutting pliers) for assembly, alignment and gripping work

- Ver long, pointed, flat rounded jaws, with tips angled by 40°

- Cutting edges with bite type cut for soft, medium-hard and hard wire; cutting capacity for medium-hard wire 3.2 Ø mm, cutting capacity for hard wire 2.2 Ø mm

- Forged from vanadium electric steel and oil-hardened; cutting edges additionally induction hardened to approx. 61 HRC for exceptionally high cutting force

- Length 200 mm

- Weight 197 g

- Handles with multi-component grips

Additional products