Product Description

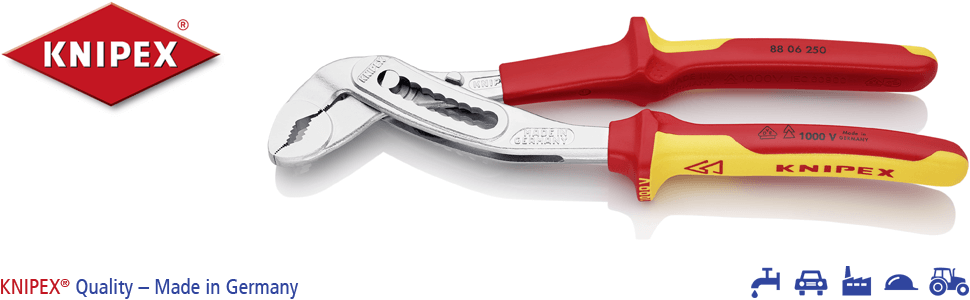

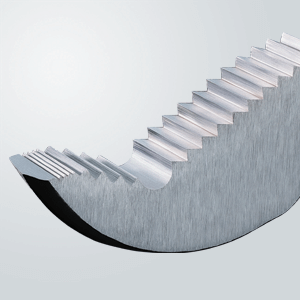

good access to the workpiece due to slim size of head and joint area. more output and comfort compared to conventional water pump pliers of the same length: 9-notch adjustment positioning for 30 % more gripping capacity. Self-locking on pipes and nuts: no slipping on the workpiece and low handforce required. Gripping surfaces with special hardened teeth, teeth hardness approx. 61 HRC: high wear resistance and stable gripping. Box-joint design for high stability due to double guide. Robust construction, insensitive to dirt; particularly suitable for outdoor work. Pinch guard prevents operators' fingers being pinched.

Technical attributes

| Length | : | 240 mm | |

| Width | : | 73 mm | |

| Height | : | 28 mm | |

| Weight | : | 374 g |

Documents

Video

Detailed description

| Energy-saving, tough and slim water pump pliers Full torque on round parts and nuts thanks to self-locking effect After gripping into the work piece, the Knipex Alligator holds onto pipes and nuts under load by itself. This self-locking effect is possible thanks to the special jaw geometry developed by Knipex. The user does not need to press the handles together, but can convert all energy directly into torque. This feature pays off in particular when loosening bolted connections that have become stuck. |

Compact design – big gripping capacity

As compact as these pliers are, the possible grip widths are surprisingly large due to the 9-step locking adjustment: round parts up to 50 mm (2 inches) and nuts up to 46 mm, which is 30 % more than with standard water pump pliers of the same size. With the non-slip multi-component grips that insulate up to 1000 volts, the Knipex Alligator 88 06 250 is ideal for electricians working on electrical installations and – with the right training – even for work on live parts.

Stable and wear-resistant – thanks to the chrome plating also when used outside

The Knipex Alligator with its box joint design and double guide offers very high stability for professional use. The teeth on the gripping surfaces have been induction hardened to approx. 61 HRC. This assures a very long tool life with an ever biting hold on the component. The Knipex Alligator is sturdily built, easy to clean and thus an ideal tool for working outdoors. In the 88 06 250 version, the Knipex Alligator is chrome-plated. The chrome plating protects the pliers from rust, for example if they are kept permanently in the vehicle of the craftsman where condensation may arise due to changing temperatures. In accordance with IEC 60900 (DIN EN 60900), they are suitable for work on live parts up to 1000 V– subject to the fitter having the required certification.

| Knipex Alligator: several manufacturing steps for high tool quality We forge the Knipex Alligator from chrome vanadium steel and use a multiple stage hardening process to give it the ideal balance between hardness and toughness. This makes it extremely durable. To achieve a lasting secure “bite” on the work component, we use high-frequency current to bring the gripping teeth to a hardness of approx. 61 HRC. Professional users expect a tool quality that will last for several years of hard use. We therefore develop and manufacture our pliers for the most demanding users imaginable: for craftsmen. Every pair of pliers from Knipex is manufactured to the highest standards using the best materials. A purchase for many years of safe, reliable work. |

Short overview

- Energy-saving water pump pliers for a secure grip

- Self-locking effect on pipes and nuts thanks to special jaw geometry

- Large grip width (up to 2 inches / 50 mm and wrench opening 46 mm) with low weight (374 g)

- Gripping teeth induction hardened to approx. 61 HRC for a permanent, secure hold

- High stability thanks to the box joint design

- Protection from pinching due to forged closing limiter

- Made from forged chrome vanadium electric steel

- Chrome-plated for the best rust protection

- With multi-component grips which insulate up to 1000 volts

Optimised adjustment to the component through 9-step locking adjustment.

Grips self-locking round components with a diameter of up to 50 mm.

High gripping capacity: grips self- locking nuts and screws up to a diameter of 36 mm.

Due to special jaw geometry, holds firmly with self-locking onto the component even under heavy load.

Additional products