Product Description

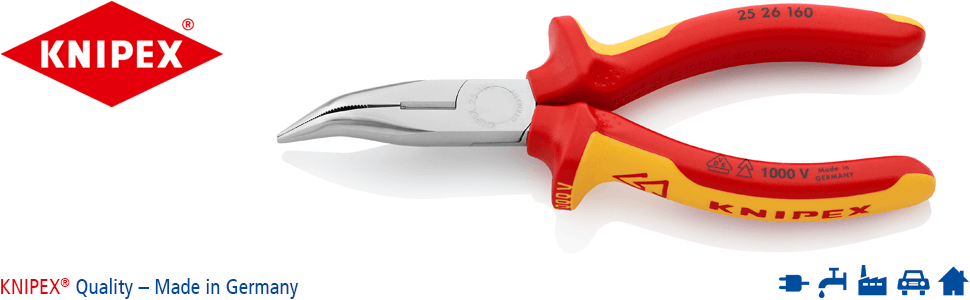

Suitable for finer gripping and cutting work. Half-round, long, tapered jaws. Knurled gripping surfaces. With cutting edges for soft, medium-hard and hard wire. Cutting edges additionally induction-hardened, cutting edge hardness approx. 61 HRC. 40° angled jaws.

Technical attributes

| Length | : | 165 mm | |

| Width | : | 51 mm | |

| Height | : | 18 mm | |

| Weight | : | 144 g |

Detailed description

|

| Ideal for applications particularly in the electrical and construction sectors For gripping, positioning and cutting The pointed needle nose pliers with tips angled at 40° combine several qualities. They can be used for the fine, measured gripping of components, but also for the powerful cutting of cable and wire. The shape of the cutting edges produces an efficient bite type cut. Thanks to additional induction hardening of the blades to approx. 61 HRC, soft wire (copper wire), medium-hard wire (fence wire) and even hard wire (wire rope fibre) can be cut efficiently using the Knipex 25 26 160 needle nose pliers. |

Stable needle nose pliers, also when twisting and during powerful cutting

The angled precision tips of the Knipex 25 26 160 made of vanadium electric steel are elastic and therefore stable when twisted.

Users can easily find the optimal amount of manual force to use. Larger components can be held firmly, while smaller components can be gripped gently using the right amount of force.

The position of the cutting edges near the joint produces a favourable level of transmission of manual force to the material to be cut. The effort required during cutting is accordingly low.

Work well also where space is restricted – and on live parts

Knipex needle nose pliers are very suitable for working in confined spaces. They are tapered at the front and the tips are at a 40° angle. This special design enables components and wire to also be gripped and held under tight, difficult to reach conditions, e.g. when repairing electrical equipment, during house installations or where on printed circuit boards in rework processes.

The slim needle nose pliers are a very welcome tool especially with electricians and fitters. Their handles are insulated, so these VDE tested pliers can also be used for work on live parts.

| Knipex quality – the needle nose pliers The VDE tested needle nose pliers from Knipex are a tool for professional users, particularly electricians. Those who work with tools every day expect a quality that permits simple and safe work. The tool must also last for many years of hard use. We therefore forge our tools from quality materials, machine them with great precision on up-to-date tool machinery, and harden them carefully using repeated heat treatment. Every pair of Knipex pliers represents more than 130 years of specialist know-how. |

Short overview

- Needle nose pliers (radio pliers) for finer gripping and cutting work

- Pointed, flat rounded jaws, at a 40° angle at the front

- Serrated gripping surfaces

- Cutting capacities: mediumhard wire (fence wire) up to Ø 2.5 mm; hard wire (wire rope fibre) up to Ø 1.6 mm

- Forged from vanadium electric steel and oil hardened

- Cutting edges additionally induction hardened; cutting edge hardness approx. 61 HRC

- Pliers are chrome-plated

- Length 160 mm

- Weight 144 g

- Insulating multi-component grips for work on live parts

- Pliers VDE tested